3M 4008-D/TR

/The prices exclude vat/

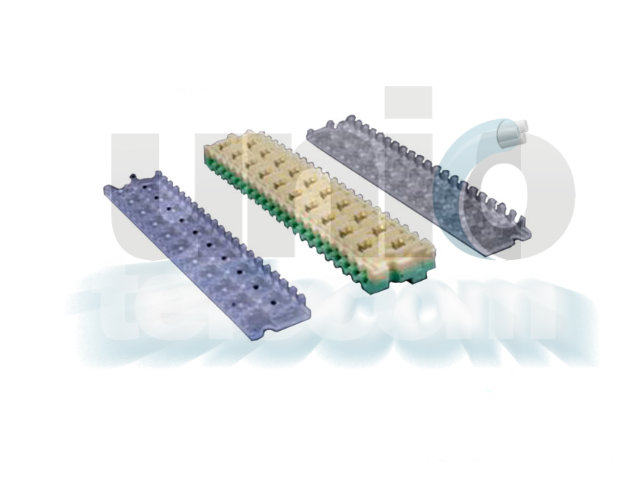

3M™ Double Coated Urethane Foam Tapes are conformable foams that offer high shear strength and are available with either a high temperature holding acrylic adhesive system or a rubber adhesive system for bonding to various types of surfaces for mounting, joining and holding.

• The natural colored urethane foam tape products vary in color from white to light yellow. The color will change to light yellow upon exposure to sunlight (ultraviolet radiation). This color change is normal and does not affect tape performance.

• 3M™Double Coated Urethane Foam Tape 4026 is available in roll form and diecut pieces. Die-cut pieces of 3M tape 4026 is available in 3/4" or 1" squares, either individual pieces double linered with an extended liner on one side or in pads of 48 squares.

• 3M™ Double Coated Urethane Foam Tape 4085 combines conformability with high immediate adhesion to most plastics including ABS, polycarbonate, acrylic, polyethylene and polypropylene as well as metal and paint. 3M tape 4085 tears easily which makes it ideal for hand application.

Application Techniques

• Bond strength is dependent upon the amount of adhesive-to-surface contact developed. Firm application pressure helps develop better adhesive contact and improve bond strength.

• To obtain optimum adhesion, the bonding surfaces must be clean, dry and well unified. Typical surface cleaning solvents are isopropyl alcohol* and water (rubbing alcohol) or heptane.

• Ideal tape application temperature range is 70°F to 100°F (21°C to 38°C). Initialtape application to surfaces at temperatures below 50°F (10°C) is not recommended because the adhesive becomes too firm to adhere readily. However, once properly applied, low temperature holding is generally satisfactory.